Inside the Fiber

By Steve Harris

How Light Rays Power Your Optical Network

Private broadband operators are making historic investments in broadband infrastructure around the globe, driving a surge in fiber optic deployments and next-generation access networks to expand connectivity and enhance digital services. Operators are pushing millions of kilometers (km) of fiber into new areas of the country, creating one of the largest fiber optic buildouts in history. Increased demand for fiber optic cables, splicing equipment, and skilled labor is straining supply chains while fueling innovation. Operators are expanding fiber infrastructure to support hybrid fiber/coax (HFC) networks, fiber deep (FD), distributed access architecture (DAA), fixed wireless access (FWA), and passive optical networks (PON), driving fiber-to-the-home (FTTH) expansion.

With all the investment centered around fiber optics, it is essential for our fiber technicians, splicing specialists, network engineers, project managers, quality control (QC) personnel, and other industry professionals to have a solid understanding of fundamental fiber concepts. This article explores the fundamental principles of optical refraction, total internal reflection (TIR), the essential roles of the fiber core and cladding, and attenuation in optical signal transmission.

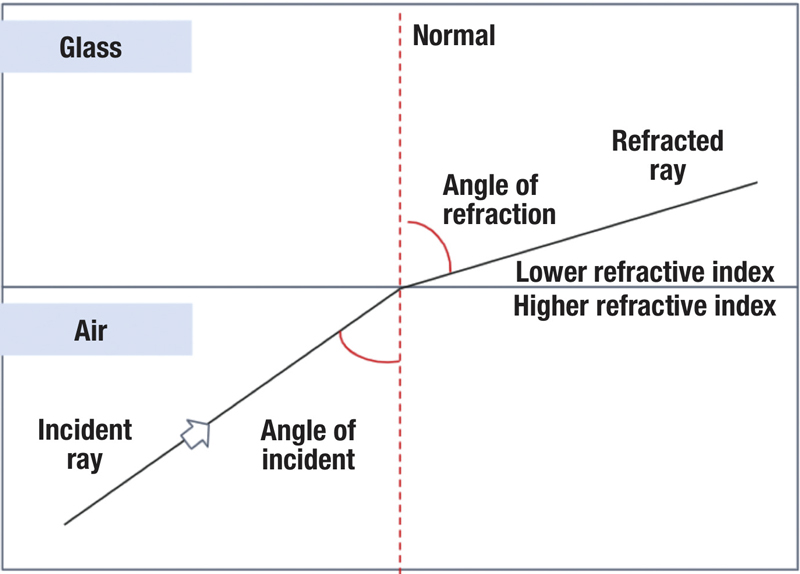

Optical refraction is key to how fiber optic devices function. The speed of a light ray depends on the material it travels through, such as glass. The index of refraction (IoR) is the ratio of the speed of light in a material (e.g., glass) to the speed of light in a vacuum (free space), a fundamental constant in physics. The IoR indicates how much a light ray slows down as it moves through a material compared to its speed in a vacuum, and it also determines how much the light ray bends or refracts when entering a material like glass or plastic, as shown in Figure 1. While plastic optical fibers (POF) are less common than glass fibers, they are used in certain applications, particularly in consumer electronics. Generally, the lower the refractive index, the faster the light ray travels through the material.

Table 1. Refractive Indexes.

In the field, loose fiber connectors can affect how light rays travel through our networks. When it comes to the IoR, a loose connector allows light rays to travel through more air than through glass fiber, potentially causing part of the signal to escape and leading to signal loss. Additionally, damaged fiber can alter the IoR, further contributing to signal loss in the network. An operator’s optical power budget defines the allowable amount of loss in the network, ensuring that performance remains within acceptable limits. However, poor craft and an improperly trained workforce can exceed the budget.

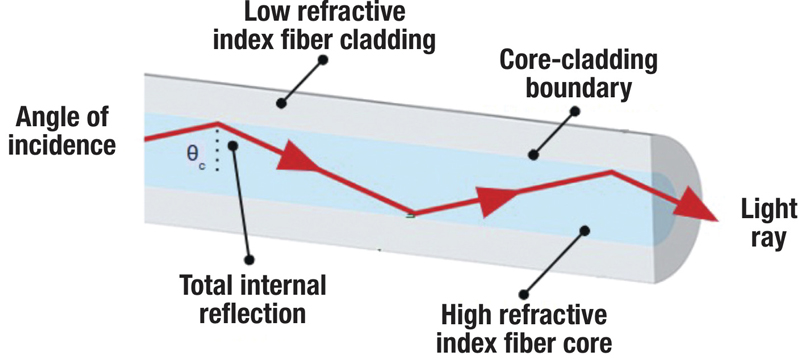

Maintaining TIR is essential, as it enables a light ray to travel long distances through optical fiber networks with minimal loss. TIR occurs when a light ray within the fiber core strikes the core-cladding boundary at an angle greater than the critical angle (θc), as shown in Figure 2, causing the light ray to reflect into the fiber’s core rather than escape through the fiber’s cladding.

Figure 1. Index of refraction of optical fiber.

Optical fibers consist of a high-refractive-index core surrounded by a lower-refractive-index cladding—a crucial difference that allows TIR to occur. The refractive index determines how much a material bends a light ray. As long as TIR conditions are met, the light ray continues to reflect along the fiber’s core-cladding boundary, efficiently guiding the light ray over long distances. The critical angle is aptly named, as its value is crucial to the proper operation of our optical networks.

However, a macrobend—a significant bend in the fiber—can cause light rays to escape the fiber’s core, leading to increased loss of signal, or the weakening of the optical light ray. This directly impacts the optical power budget of our networks. If the power budget is exceeded, transmission distance decreases, signal quality degrades, and overall network performance suffers, ultimately affecting the customer quality of experience (QoE). In severe cases, exceeding the optical power budget can trigger alarms in customer end devices and disrupt services.

Figure 2. Total internal reflection.

Another factor to monitor is the misalignment of the fiber core and cladding during processes like fusion splicing, mechanical splicing, and SC/APC connectorization. If the core is not correctly aligned with the cladding, it can interfere with the TIR process, reducing signal efficiency. Additionally, when splicing older fibers with newer ones that have different properties, inconsistencies in the fibers’ refractive indices can disrupt light ray transmission. This can also occur when using multiple optical fiber cable vendors where the fiber specifications may not align. Contaminants such as dust or oil on the fiber or connectors can cause scattering or partial reflection of the light ray, further disrupting TIR. This results in less optical light power being transmitted through the fiber, ultimately degrading signal quality and affecting the optical power budget and network performance.

A final key concept, and an extrinsic factor that can be managed, is attenuation—the gradual reduction in optical signal strength as it propagates through the fiber. As discussed, IoR, TIR, and the fiber core and cladding can influence optical network attenuation or signal loss. A properly trained technician will be able to avoid factors that impact attenuation. Most technicians today have access to optical power meters (OPMs) that can identify attenuation faults in the network.

Mastering these fundamental concepts is crucial to the continued success and growth of our fiber optic networks. As we see massive investments through programs like BEAD, fiber infrastructures will continue to expand, covering new regions and supporting an increasing range of applications. However, this rapid growth demands not only the physical installation of fiber but also a deep understanding of the underlying principles that impact its performance. This includes maintaining optimal conditions for TIR, ensuring proper alignment of fiber components, preventing undesired signal loss, practicing good craft, and carefully managing the optical power budget to avoid exceeding attenuation limits. The challenge is not just building the network, but also maintaining it with precision and care to ensure long-term reliability and performance for our customers. As fiber networks evolve, the need for skilled technicians, engineers, and operators with a strong grasp of these concepts becomes more critical. Continued innovation, training, and quality assurance will be key factors in ensuring that the growing fiber infrastructure meets the demands of future communication and connectivity while delivering the best experience to end-users.

Connect with Steve Harris to arrange hands-on fiber optics training for your team. As a seasoned expert in the field, Steve Harris has extensive experience in fiber optic technology and training.

Steven Harris

Steve Harris is a globally recognized expert in telecommunications and learning and development, with over 30 years of experience in technology, network engineering, and workforce education. He most recently served as VP of Global Commercial Relationships at SCTE / CableLabs, where he played a pivotal role in delivering international education programs, shaping industry standards, and fostering strategic partnerships. A Cable TV Pioneer, SCTE Senior Member, and recipient of SCTE’s Excellence in L&D Award, Steve is also a patent holder and an advocate for advancing broadband education. He has authored numerous peer-reviewed papers and influential publications and currently serves as an instructor for Cisco, CompTIA, and CWNP. In addition, he actively supports industry growth as an ambassador for organizations such as the Broadband Communications Association of Pennsylvania and NATE.

Images provided by author, Shutterstock.