The Wins of Our Fathers

Coaxial cable from the past still meeting the demands of the present, and preparing for the future

By Bill O’Donnell

Modern cable systems are the result of the work of three historic figures. In the late 1940s and early ’50s Jimmy Davidson of Arkansas, John Walson of Pennsylvania, and Ed Parsons from Oregon were the fathers of the traditional RF distribution system. What makes their stories so exceptional is that, while working a continent apart, they each arrived at similar solutions almost simultaneously.

The use of coaxial cable (coax) was key to the beginning of traditional network architecture, and doesn’t appear to be going away anytime soon. While the early architectures are decidedly different than today’s HFC network architecture, the key element, hardline coaxial cable, has largely remained unchanged. The foresight of early engineers combining the need for performance with the electrical principles that would be required for hardline cable, still holds true to this day.

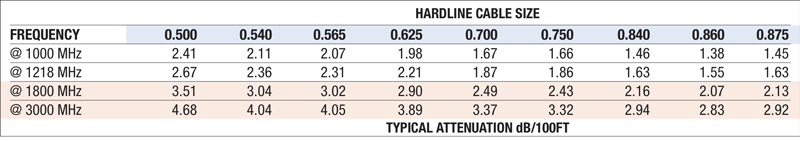

With the introduction of DOCSIS 3.1 as well as the development of distributed access architectures like R-PHY, increased bandwidth needs have continued to push network growth from less than 550 MHz to our current 1.218 GHz. And the need to extend spectrum to 1.8 GHz and 3 GHz looms. Such bandwidth increases force changes to the active and passive products that connect to the network. Despite this, the hardline coaxial cable itself has remained unchanged. There has been very little innovation needed because early engineers knew what the product would be capable of in the future.

In the 1980s, however, work was undertaken to reduce coax attenuation, allowing deeper network extension while providing for economical amplifier placement. Engineers developed an aluminum sheath tube design that allows a larger dielectric without changing the outside diameter of the cable. This new design worked well, but introduced additional challenges such as increased sheath resistance, mechanical integrity issues and reduced corrosion resistance.

Subsequently, engineers determined that the best approach to ensure the cables would perform for many years to come would be achieved by bonding the cable components inside of the product. Bonding the dielectric to the aluminum provided enhanced handling as well as core pull-out protection during temperature extremes. Bonding the jacket to the aluminum tube further enhanced the product’s corrosion resistance. Bonding the center conductor to the dielectric provided corrosion and moisture ingress protection. Such forward-thinking design allows a service life of many years, while still expanding spectrum.

Future challenges will be the end-of-line targets, especially when it comes to linear tilt profiles when increasing bandwidth from 1.218 GHz through 1.8 GHz and on to 3 GHz. Additional engineering will be required to reduce distance between spans, reduce amplifiers, decrease the distance from node to subscriber and ultimately move to node + 0 architecture. All of these changes will substantially increase the delivered signal-to-noise ratio (SNR) assisting with delivering error free connections.

Note in the chart that bandwidth increases will result in substantial attenuation increases requiring operators to change the design of their plant.

Millions of miles of hardline have been installed over the years and this plant won’t be simply abandoned. Instead, it will likely evolve as wireless technology continues to emerge. As 5G platforms roll out serving IoT applications that require low latency, radios will need to be located extremely close to these devices. Power availability for these radios may be one challenge that existing hardline can be adapted to serve. While not without challenges, coax could become the powering source behind the wireless revolution.

The cable designs of the 1940s were probably never expected to achieve what they are able to today, but have proven that their design will hold a place in history. Coax has the potential to continue to contribute as our networks evolve.

Bill O’Donnell,

Director of Product Management,

Amphenol Broadband Solutions

bodonnell@abs-go.com

Bill O’Donnell is the Director of Product Management for Amphenol Broadband Solutions and has been working in the telecommunications industry for over 20 years. In this role, Bill works with network providers to help define their challenges for which he draws on the corporation’s global resources to develop innovative solutions.