Reliable and Efficient Fiber Optic Networks

By Steve Harris –

Following best practices in optical fiber construction

Optical fiber construction plays a pivotal role in contemporary broadband and telecommunication networks. It encompasses the comprehensive process of planning, designing, installing, maintaining, and repairing fiber optic cables and equipment, facilitating the transmission of data over extended distances to our customers. The operational excellence of the fiber optic network is intricately linked to the proficiency of the workforce supporting it. Hence, adhering to best practices like those available from SCTE in workforce development within optical fiber construction is imperative to guarantee the network’s reliability, efficiency, and cost-effectiveness.

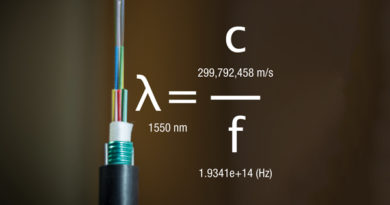

Optical fiber construction commences with the implementation of a robust optical safety program, as depicted by the equipment in Figure #1. It is imperative to comprehend the hazards associated with working with optical fibers and related equipment, both in aerial and underground settings. The Occupational Safety and Health Administration (OSHA) has established guidelines for working with optical fibers, and these guidelines are seamlessly integrated into SCTE’s training programs. The primary objective is to safeguard our workers from exposure to hazardous materials and to ensure a secure work environment. By meticulously adhering to OSHA guidelines and SCTE best practices, operators can significantly minimize the risk of workforce injuries, thereby ensuring the installation of the optical fiber network in a safe and secure manner.

Figure 1. Sample safety gear: glasses, hat, live fiber id, gloves and voltage detector

Fiber network design and application are paramount for understanding the fundamental operation of components within a fiber optic network. This encompasses the recognition of common fiber network topologies (e.g., distributed split) and a comprehensive understanding of the losses inherent in a system’s design. Moreover, distinct types of fiber networks, such as HFC, fiber deep, distributed access architectures (DAA), and fiber to the premise (FTTP), demand cutting-edge skills. By mastering these concepts, our workforce can proficiently plan, design and install fiber optic networks that boast reliability and efficiency.

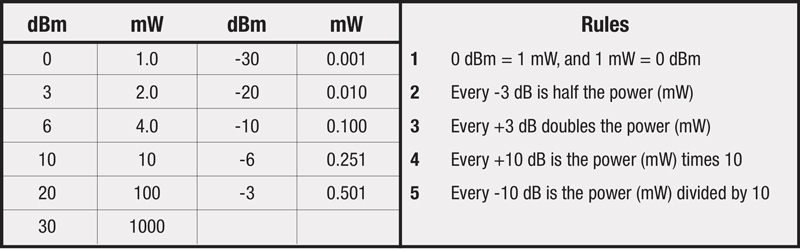

A significant aspect of fiber designs involves the execution of optical conversions between relative (dBm) and absolute (mW) optical values, as illustrated in Figure #2. Additionally, our workforce must possess the capability to calculate both the relative and absolute power budget of an optical link. Furthermore, they should be adept at describing key elements of an optical link, including total loss, splice averaging, and power margin. A thorough comprehension of these concepts is paramount to ensuring that the optical fiber network operates at peak efficiency.

Beyond design and application, optical cable preparation plays a crucial role in achieving the necessary connectivity for our customers. Proficiency in recognizing the steps involved in opening various fiber cables, connectorization, splice preparation, and explaining the functions of a fiber enclosure are essential skills. Adhering to SCTE’s best practices in preparation is key to ensuring that the fiber optic network is constructed and connected accurately from the outset. When it comes to splices and connectors, specific recommended practices are also essential for the proper execution of a low-loss mechanical splice and fusion splice. It is imperative to correctly classify common connector types and polishes used within an optical network, as well as to identify the intrinsic and extrinsic factors that contribute to optical loss in our networks. Through a comprehensive understanding of these concepts, we can guarantee that the fiber optic network operates with reliability and efficiency.

To construct these optical networks, the fundamentals of construction for aerial and underground outside plants (OSP) are imperative. Our workforce should be proficient in describing the equipment employed for installing optical cables and interpreting SCTE’s endorsed construction practices for placing both aerial and underground optical fiber cables. Equally crucial to network building are the restoration techniques meticulously developed by SCTE. Following a storm or natural disaster that impacts the network, our workforce must implement recommended restoration practices and procedures utilized by operators. It is essential to develop a comprehensive optical restoration plan, ensuring that our networks are restored promptly while adhering to allocated operational expenses (OpEx).

Optical networks require a well-thought-out maintenance plan, along with proactive procedures. Utilizing the latest tools and recognizing common faults allow us to reduce the impact on our customers while increasing the reliability of the network. Our workforce will be working with visual fault locators (VFL), fiber scopes, optical power meters (OPM), optical light sources (OLS), and optical time domain reflectometers (OTDRs); see Figure #3. SCTE has developed an OSP registry of Technical Corporate Alliance Program members who collaborate with SCTE in delivering hands-on skills in their boot camps (a.k.a., onsite training programs).

Figure 2. dBm to mW conversion table

In conclusion, adherence to best practices in optical fiber construction is crucial for guaranteeing the reliability, efficiency, and cost-effectiveness of our fiber optic networks. By grasping the concepts outlined in this discussion on optical fiber construction, our workforce can adeptly plan, design, install, and maintain fiber optic networks that not only meet customer needs but also deliver a superior quality experience. The implementation of best practices has proven instrumental for operators, leading to improvements in OpEx through the reduction of truck rolls, call center customer calls, and streamlined service responses to construction failures. To initiate a program tailored to your workforce and aligned with specific job role descriptions, please reach out to us at cap@scte.org.

Figure 3. Optical tools: VFLs, scope, OPM, OLS/OTDR

Steven Harris

Steven Harris

VP Global Market Development,

SCTE® a subsidiary of CableLabs®

Steve is responsible for overseeing the architecture and evolution of education programs, professional credentialing, and customized career learning journeys, as well as international business development and partnerships for SCTE.

Figures provided by author.