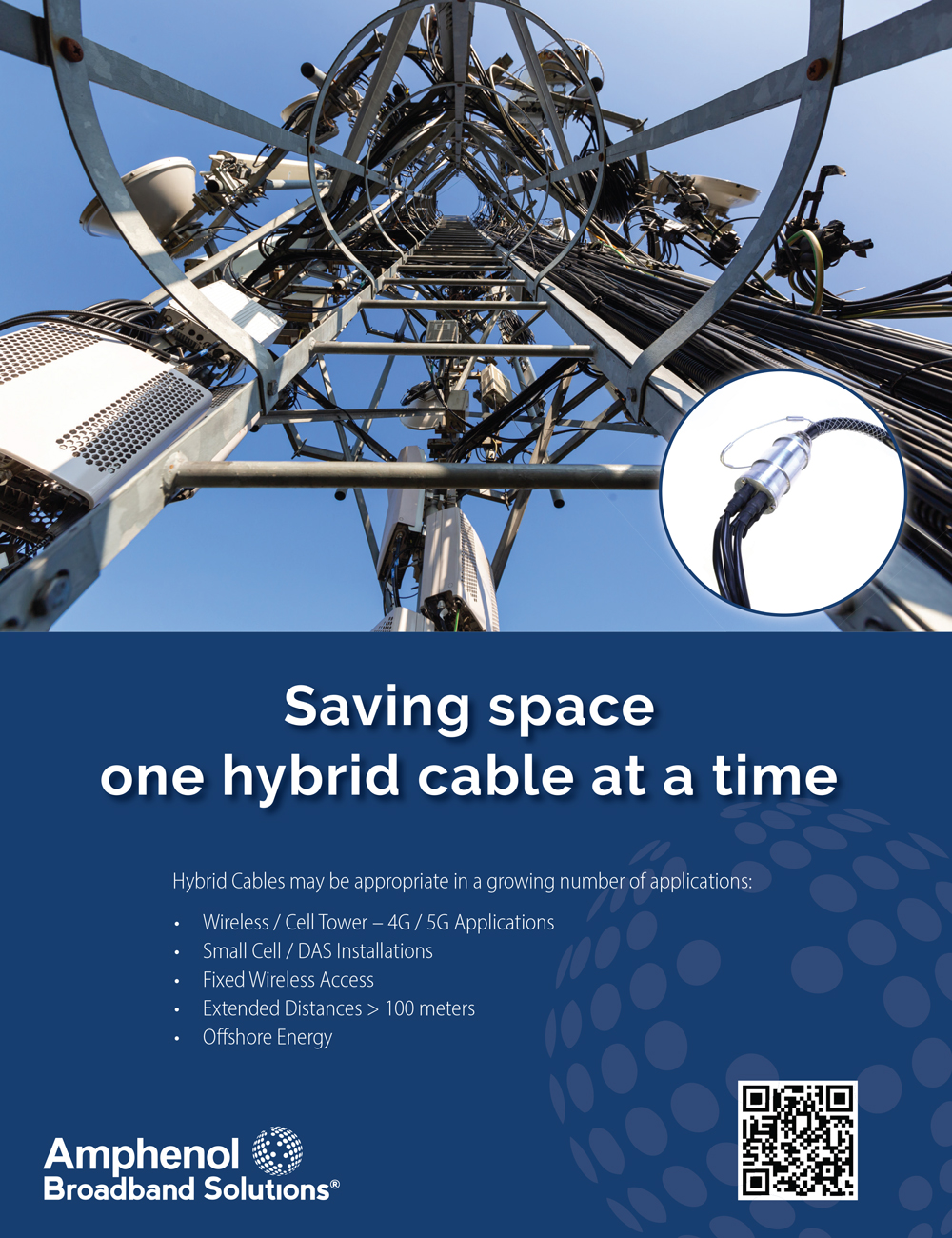

Hybrid Cables Reduce Network Complexity and Costs

By Timothy Cooke

In June 2019, Broadband Library published an article entitled “Hybrid Cables Simplify FTTA Deployment.” The focus was on a single application, wireless cell towers, that can benefit from the use of these cables. In fact, this use is only one of many that might take advantage of this technology.

Hybrid cable can be broadly defined as two (or more) different types of cable contained within the same sheath. Perhaps most common is a combination of optical fibers along with copper power cable. Such a cabling option eliminates the need to run multiple cables each time equipment reinforcement is necessary. Additionally, this approach can reduce the amount of needed cable, and cable installation time, by as much as 50%.

Let’s examine a few possibilities:

Wireless / cell tower — 4G / 5G applications

In many applications, copper coaxial cables are being replaced by fiber-copper hybrid cables for cell tower deployments and upgrades. When power cable is added to the same sheath, there is less space required to power and carry information. Additionally, the newer fiber component cable offers both higher bandwidth as well as a greater upper frequency than legacy copper coax cables.

Small cell / DAS installations

There is a growing proliferation of distributed antenna systems (DAS) as well as small cell antennas being deployed to meet wireless needs in buildings, on campuses as well as in neighborhoods. Simplifying the installation of cable up the utility poles, street-lamps, rooftops, etc., will speed these installations, bringing wireless broadband to potentially thousands of locations sooner than would otherwise be possible. Hybrid designs that use smaller conductors such as 10, 12 or even 14 AWG are now being considered or used in a growing number of applications.

Fixed wireless access

The demands on FWA continue to grow as the technology is used to provide signal for applications in homes not necessarily accessible with traditional cable networks. Still, consumers expect that their service will allow them to view multiple 4K TVs in their home. Thus, FWA requires low latency along with high bandwidth and throughput offered with the use of hybrid cables.

Extended distances (e.g,. > 100 meters)

It is difficult to break the 100-meter distance using Class 2 power over Ethernet (PoE) cables (CAT6). Further, not all Class 2 CAT6 cables are even PoE capable. While fiber may offer an alternative, deployment of the needed transmitters and receivers may be prohibitively expensive or not possible. In such cases copper conductors within a hybrid design may provide all of the advantages offered by fiber over these longer distances. Current hybrid designs which incorporate THNH conductors are able to transmit power (non-PoE, Class 2 circuits) at distances greater than 100 meters, with some designs even having Class 3 power capability.

Offshore energy

Some companies are designing and building hybrid composite submarine cables. A recent article in offshore-energy.biz describes a hybrid cable designed to address inter-island 5G Internet demand, while also taking advantage of solar power being generated in Singapore. The article states “The new generation cable will be especially designed for faster deployment of inter-island connectivity to share high-capacity data and high voltage power across islands to facilitate next-generation smart grid infrastructure and connectivity in Singapore and Asia.”

As the world continues to become more connected while also seeking more efficient power, it is clear that new applications, and the respective cables that can make them possible, will emerge. These hybrid designs will incorporate copper conductors, fiber optic components and CAT6 cables, with the data cable supplying control and monitoring. Indeed, hybrid cables from a highly experienced manufacturer offer a solid solution to growing capacity as efficiently as possible.

Timothy Cooke,

Product Manager,

Amphenol

Timothy Cooke is Product Manager for Amphenol Broadband Solutions. In this role, he supports all facets of engineering and product development through collaborative work with customers as well as industry standards organizations.

Shutterstock