Decoding the Fiber Optic Color Codes

By Steve Harris –

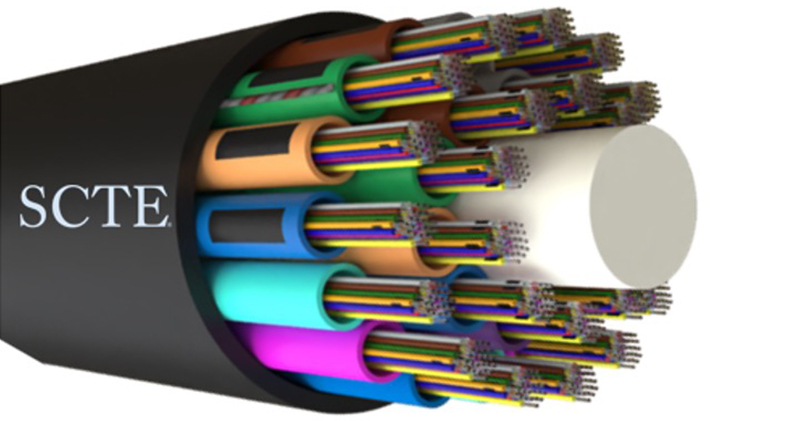

In the intricate web of modern optical telecommunication networks, clarity and consistency are paramount when offering a great customer quality of experience (QoE). Through the maze of our optical cables and patch panels, the ANSI/TIA-568 and TIA-598-C color codes stand out as our North Star for organization and standardization, especially in fiber optics. As the backbone of our digital infrastructures, understanding these color codes is crucial for technicians, engineers, and anyone navigating the world of fiber optic connectivity.

The American National Standards Institute (ANSI) and the Telecommunications Industry Association (TIA) jointly developed the ANSI/TIA-568 standard to ensure uniformity and compatibility in telecommunications cabling infrastructure. The Electronic Industries Alliance (EIA) with ANSI/TIA also created standard 598 in 2001, defining identification schemes for fibers, buffer tubed fibers, fiber units, and groups of fiber units within an outside plant (OSP) and premises optical fiber cables. TIA-598-C refreshed the ANSI/TIA/EIA 598 to include new jacket colors and Munsell color definitions from ANSI/EIA 359-A. These standards encompass various elements of our fiber optic cabling systems, including the color codes that play a pivotal role in simplifying our installations, maintenance, and troubleshooting processes.

The ANSI/TIA-568 color code for fiber optics designates specific colors to individual fibers and connectors, facilitating quick identification, proper alignment, and rapid troubleshooting. Here’s a breakdown of the key colors and their corresponding roles:

- Orange: Typically designated for multimode fiber (MMF) cables. In installations where MMF is present, each fiber often has an orange coating for easy identification.

- Aqua: This color is commonly used for newer MMF cables offering greater bandwidth and speed. The use of aqua distinguishes these cables from their traditional orange counterparts, especially in high-density installations. See my Broadband Library article on Deciphering the OM Fiber Designation (https://broadbandlibrary.com/om5/).

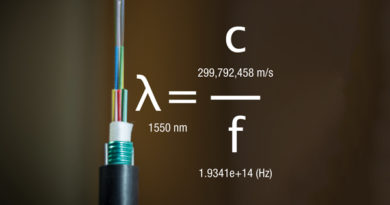

- Yellow: Primarily assigned to single-mode fiber cables. Single-mode fibers have a smaller core size, enabling them to transmit data over longer distances with minimal signal loss.

- Blue, Green/Lime Green, Brown, Slate, and Magenta: These colors are often used for various purposes, such as the identification of specific fibers within a cable, MMF OM designations, or distinguishing between different types of connectors (e.g., green APC).

- White: White fiber cables are frequently employed for indoor applications, where aesthetics play a crucial role. They blend seamlessly with white walls and ceilings, maintaining a clean and discreet appearance.

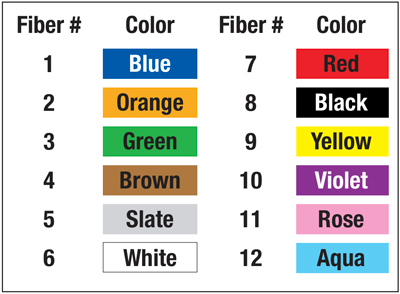

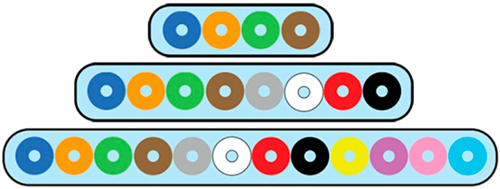

The TIA-598-C color code for fiber optics designates specific colors to individual fibers inside the cable or typically within each buffer tube in a loose tube fiber cable; individual fibers will be color-coded for identification. Here’s a breakdown of the fiber numbers and their corresponding color:

Figure 1. TIA-598-C color code for up to a 144F cable

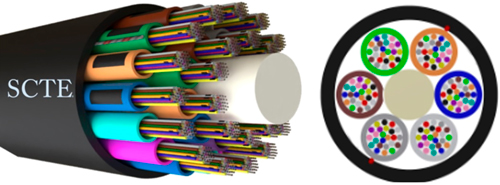

Please note that fiber buffer tubes maintain the same TIA-598-C color sequence as the 12 fibers (12F) themselves for up to 12 tubes. For example, tube one of the fiber will be “blue” with 12F colored as shown in Figure 1. From tubes 13 to 24, the colors will repeat with a colored tracer or ring mark (IEC), typically black on the tube as shown in Figure 2. The black fiber will generally feature a yellow tracer.

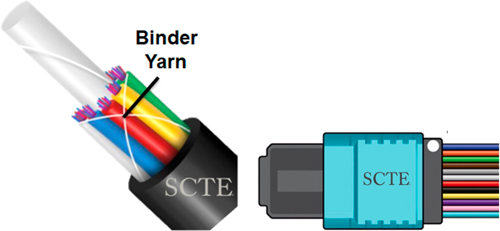

Tubes 25 to 36 will continue the color sequence with an orange tracer, and tubes 37 to 48 (Figure 2) will utilize a green tracer, adhering to the same color code sequence for the tracer. For high fiber count buffer tubes containing 24F (1,152F) or 36F (1,728F), binder tape or binder yarn is utilized to separate fibers into groups of 12. Ribbon fiber cables and multi-fiber push on (MPO) cables also adhere to the TIA-598-C color sequence (Figure 4).

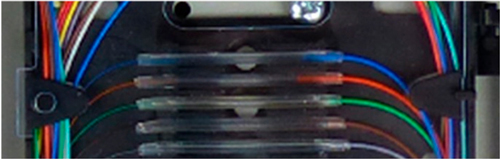

In fiber splicing, fibers of similar colors and numbers are typically spliced together to ensure continuity throughout an optical run. Refer to your fiber maps and documentation for variances (Figure 5).

Furthermore, be aware of the International Electrotechnical Commission (IEC) 60304 standard that offers a different color sequence of: 1 Red, 2 Green, 3 Blue, 4 Yellow, 5 White, 6 Grey, 7 Brown, 8 Violet, 9 Turquoise, 10 Black, 11 Orange, and 12 Pink. The IEC standard may be encountered in Europe.

Understanding the industry standard color codes empowers professionals to navigate our broadband networks with confidence and precision. Whether deploying new greenfield installations, expanding existing brownfield networks, or troubleshooting connectivity issues, adherence to these color codes streamlines our operations and ensures seamless integration of fiber optic components.

As technology continues to evolve and demand for broadband data transmission grows, these color codes remain a firm cornerstone of our fiber optic connectivity. Its adaptability and clarity pave the way for future innovations in network infrastructure, enabling the seamless integration of emerging technologies (e.g., 25G PON) and the realization of new possibilities in communication and data exchange (e.g., coherent PON).

In conclusion, for those eager to delve deeper into the realm of fiber optics, I invite you to explore my “Fiber Source” column. Additionally, SCTE has recently launched the revitalized Broadband Fiber Transport Specialist (BFTS) program, which comprehensively covers various facets of optical signal distribution within access and transport network architectures.

Figure 2. 576F Microduct loose tube and 144F with 24F buffer tubes

Figure 3. Example of binder yarn and MPO cable aligned to TIA-598-C

Figure 4. Ribbon fiber, 4F, 8F and 12F

Figure 5. Splicing example

Steven Harris

Steven Harris

VP Global Market Development,

SCTE® a subsidiary of CableLabs®

Steve is responsible for overseeing the architecture and evolution of education programs, professional credentialing, and customized career learning journeys, as well as international business development and partnerships for SCTE.

Figures provided by author.