Cleaning Optics Is a Practice Not a Project

By Steven Harris

The trend in the cable industry going forward will be to deploy an increased number of fiber-rich networks that include sophisticated optic connections, equipment, and cabling. New architectures like distributed access, fiber deep (node + 0), and fiber to the x (FTTx) all take advantage of new fiber connectivity in the core, aggregation, access, and premises networks. Many of these fiber networks use single mode fiber (SMF) connections with an 8 micrometer or micron (μm) core, where a dust particle in an SMF core is like a clog in a premises water drain. These clogs may block a single optical wavelength or where operators are deploying wavelength division multiplexing (WDM), many wavelengths at once. Remember that the dust, scratches, and defects we are referring to here cannot be seen with the human eye. For example, in a fiber deep architecture a single dust particle may be able to take out a mother node (see my previous article on fiber deep) and all fiber deep nodes that are fed from the mother node. All of our new deployments in fiber optics will introduce new core competencies required by cable operators for their workforce to deploy, operate and troubleshoot fiber networks.

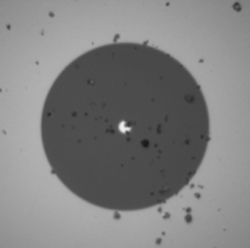

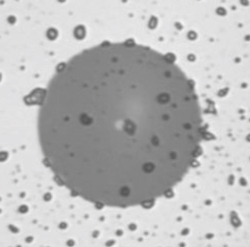

Whenever an optical connection occurs, there is a chance that contaminants may enter our networks. There is also vendor data to show that optical dust caps and/or new optical jumpers out of the box may also introduce contaminants. It is always important to inspect before you connect, never assume the optical connections, hub bulkheads, equipment ports, pluggable optics and test equipment ports are clean! Contaminants may be introduced by people who mishandle optical connections. Mishandling these connections introduces oils (e.g., from touching with fingers), dust, residue from poor wiping techniques, lint, condensation deposits, contaminated alcohol, not using connector caps, contaminated caps, etc.

It is also important that cable personnel visually inspect both sides of a connection, meaning the fiber optic connector and any other ports that will be utilized. Visually inspecting both sides of an optical connection with an appropriate instrument will lead to improved optical health and reduction in damaged connections in our networks. For example, visually inspecting and cleaning fiber connections improves many of our customer affecting metrics like optical power levels, end of line RF power levels, attenuation (e.g., reducing reflectance), modulation error ratio (MER), pre-forward error correction (FEC) bit error ratio (BER), and post-FEC BER.

In addition, proper cleaning of connectors will reduce connector to port mating damage, as hard contaminants may lead to scratches on the silica glass. With all cleaning mentioned, it is important to visually re-inspect to make sure proper cleaning was completed.

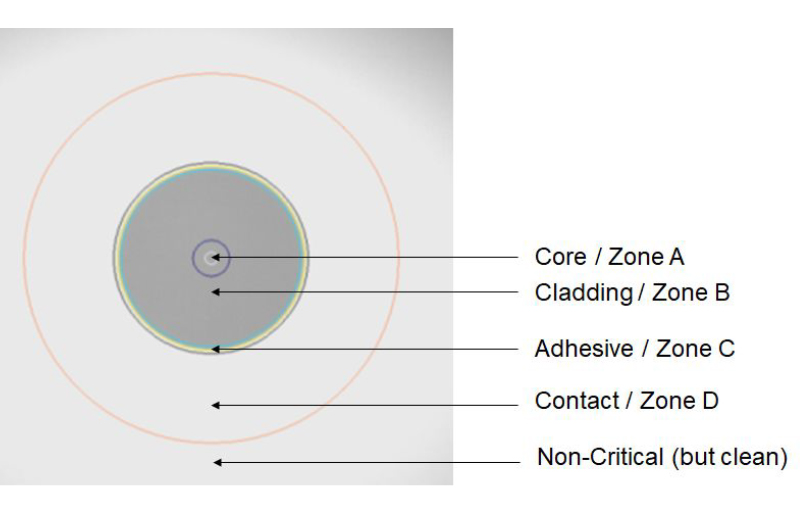

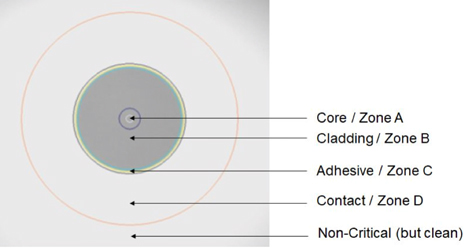

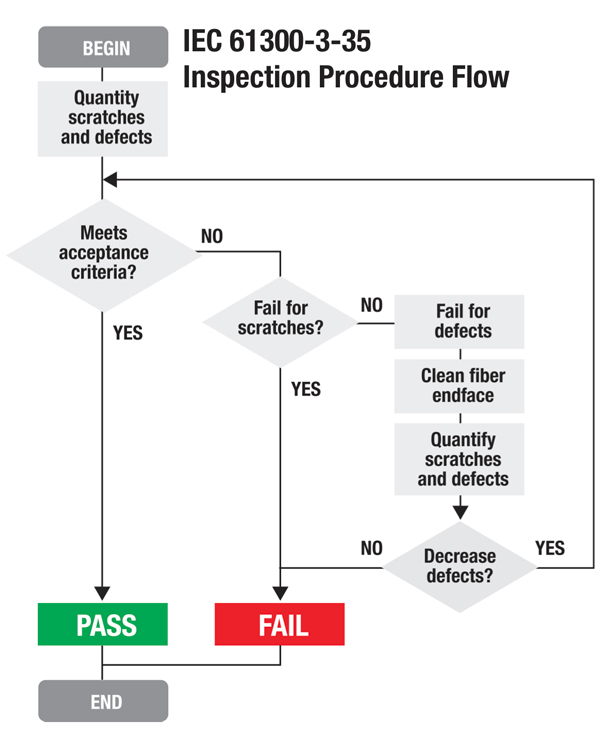

What is the recommended method that should be used by cable operators to maintain their optic connections? The answer is an International Electrotechnical Commission (IEC) standard known as 61300-3-35, which sets the requirements for connector quality. Another standard is known as IPC or referred to today as the Association Connecting Electronics Industries (ACEI), however, our focus will be the IEC standard for this article as many of our cable vendors support the IEC method. The IEC standard was developed to guide the telecommunications industry in determining the types of issues that may occur in multiple diameter zones of an optical connection. In the figure below an optical end face is segmented into four zones for visual inspection known as the core (A), cladding (B), adhesive (C) and contact (D).

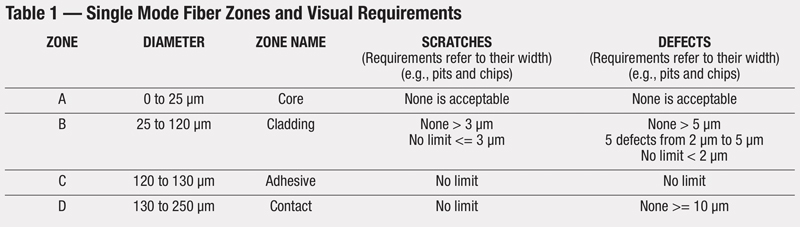

The IEC standard defines multiple diameter zones with scratch and defect tolerances for SMF and multi-mode fiber (MMF). Below are the visual requirements for SMF scratches and defects for each zone.

Notice in Table 1 that scratches and defects in the core are not allowed, replacement will be needed for jumpers and other optical equipment when a zone requirement cannot be achieved. Also, note in Table 1 that the cladding should not have scratches greater than 3 μm nor defects greater than or equal to 5 μm. In practice, fiber inspection beyond the contact zone D is recommended, making sure to evaluate overall cleanliness beyond the contact zone to maintain good craftmanship.

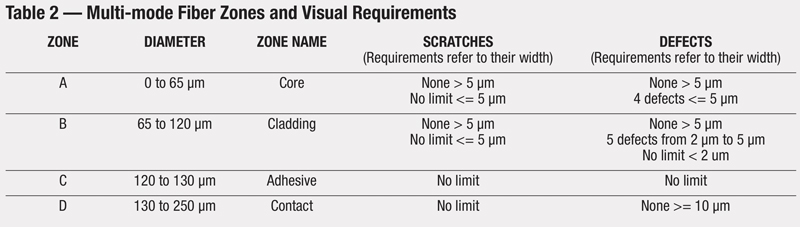

The IEC standard also defines an MMF end face. Table 2 shows the visual requirements for MMF scratches and defects for each zone.

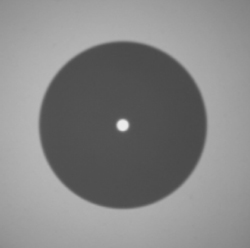

It is virtually impossible to qualify a connector against a standard such as IEC with a manual inspection process. Many optical vendors provide an automated visual inspection or microscope (scope) test instrument with analysis software. These instruments are used to grade the health of an optical connection, verifying that a connection has been properly cleaned or polished. Many of the vendors will also supply reporting options for record keeping, showing proof of compliance with IEC or IPC standards.

As operators deploy more optical connections in the network, it will be vital to handle these connections properly and with the utmost of care. Today’s network must operate with the highest reliability possible, providing the best quality of experience (QoE) for our subscribers. Many of the vendors in the cable community have shared how contamination can be the number one source of issues in our optical networks. Be sure to proactively inspect the optical connections using an automated scope that is aligned to a standard like IEC. Since most of the contaminations are not visible to the human eye, this will be a crucial step to determine if a connection is clean. Finally, after cleaning always re-inspect the connection. To learn more about fiber optics or to pursue a career in this growing field, be sure to check out SCTE·ISBE’s new certified broadband fiber installer, http://www.scte.org/BPI.

Steven Harris

Steven Harris

Senior Director, Advanced Network Technology and Instruction, Learning and Development, SCTE•ISBE

Steve Harris is the senior director of advanced network technology and instruction at SCTE•ISBE. He is a respected international telecommunications subject matter expert, sought-after presenter and principal instructor. He is responsible for the tremendous growth of SCTE•ISBE training programs and certifications for over 100,000 telecommunications professionals. He also has responsibility for the client partnership in the SCTE•ISBE Corporate Alliance Program for cable operators and vendors.