Are Staples in Coax Cable Impacting My DOCSIS speed?

By Brady Volpe

I recently posted a YouTube short (https://www.youtube.com/shorts/n5ucjCb-iGA). ) about how staples in coaxial cable can cause micro-reflections and interfere with subscriber modems. The video was well-received, and I received a lot of feedback, including real-world experiences and questions about the implications of these issues. Let’s take a closer look at this subject.

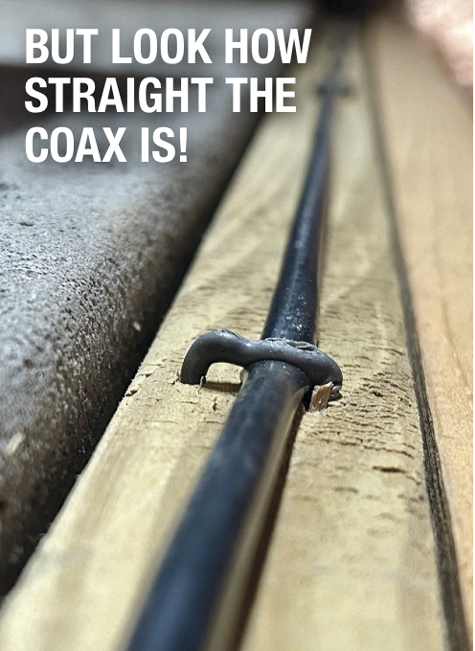

Staples in coax cable meets the real world

Let’s start off with an example of real-world feedback I received. The example goes as follows:

“I’ve had calls for this. Poor US voice quality. My worst one was the tech had rolled up some old cable and squeezed the ends to make it like a bow. He found it in his truck and unrolled it and straightened out the kinks…on the outside of the wire. The evenly spaced kinks caused part of a massive return issue. We teach techs about the staples and tell them to use the ones with the plastic insulator, but you can still dent the coax. Use staples to HOLD the wire, not to FASTEN the wire. You should be able to slowly pull a freshly stapled wire out of the staples, unless the run is really long. Can’t pull it? You’ve dented the coax.” — Todd T

Todd shared two critical points with us:

- He stated that evenly spaced kinks in coaxial cable can cause significant signal return issues, as well as a negative impact on upstream voice quality and possibly other issues.

- He suggested using staples to “hold” the cable and not secure it, preferring those with plastic insulators. He also stressed the importance of being able to pull the cable through the staple after it has been secured to ensure that it is not compressed.

This is sound advice. Now let’s understand why staples and kinks can be a problem for DOCSIS cable modems.

Calculating coax cable impedance

Coaxial cable, also known as coax or coax cable, is heavily used in the cable industry to deliver services from drops to end users and for inside wiring in subscriber’s homes. Despite its appearance, coaxial cable is surprisingly susceptible to damage, which can have a negative impact on subscribers’ quality of experience (QoE). To understand how this is possible, we must first examine the composition of coaxial cable as well as the concept of impedance.

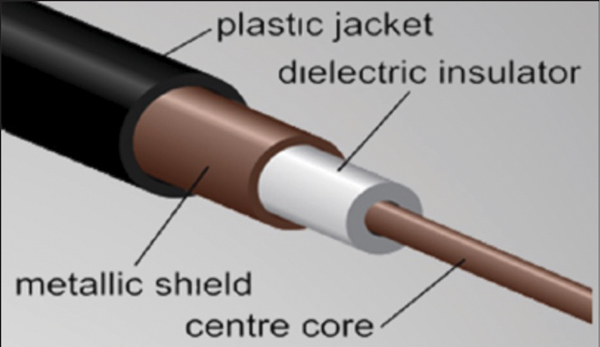

Coax cable is a two-conductor transmission line composed of a center conductor surrounded by a dielectric insulator layer, a metallic shield and a protective plastic outer jacket. The metallic shield is designed to to keep desired signals inside of the coaxial cable (that is, prevent signal leakage or egress), and undesired over-the-air signals out of the coax (prevent ingress). See Figure 1.

Figure 1. Example of physical make up of coax cable.

Coaxial cable has a specific characteristic impedance, which is typically 75 ohms in our industry. Signals from the cable modem will be reliably transmitted to the CMTS as long as the 75 ohm impedance is maintained. However, as Todd described, if the coaxial cable has a dent or kink, the characteristic impedance of the cable is no longer 75 ohms at the kink or dent. This occurs because physical damage to the cable disrupts the uniformity of its structure, resulting in variations in capacitance and inductance, which affects the cable’s characteristic impedance.

Impedance can be thought of as a barrier that electrical current must pass through in order to flow through a wire. Imagine electricity as water flowing through a pipe, the pipe itself has a certain level of friction that reduces the speed of the water flow, this friction is similar to resistance. However, when the pipe is bent or has obstacles in the way, it causes the water to change direction, this makes the water work harder to flow through the pipe, this is similar to reactance. Impedance is the combination of these two factors, resistance and reactance, that impede the flow of current through the wire. It’s measured in units called ohms, similar to how we measure the flow of water through a pipe, in gallons or liters.

We can calculate the impedance of a coax cable as follows:

where:

Z0 is the characteristic impedance of the cable, measured in ohms (Ω)

D is the inside diameter of the shield

d is the diameter of the center conductor

er is the relative permittivity of the dielectric

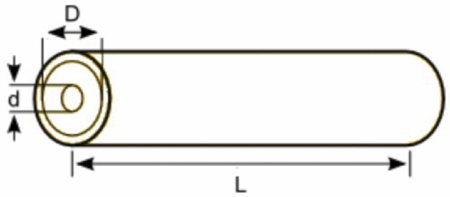

It is important to note that the ratio of D/d is the critical variable (in addition to er, but this will remain constant) that affects the impedance in the formula for calculating the impedance of a coaxial cable. This means that if the center conductor and/or shield diameter of the coaxial cable changes, the cable’s impedance will change as well. The relationship between the outer and inner diameters is depicted in Figure 2. Note that the length of the coax cable (L) has no impact on the coax cable’s impedance.

Figure 2. Inner to outer diameter ratio, which directly impacts a coax cable’s 75 ohm impedance.

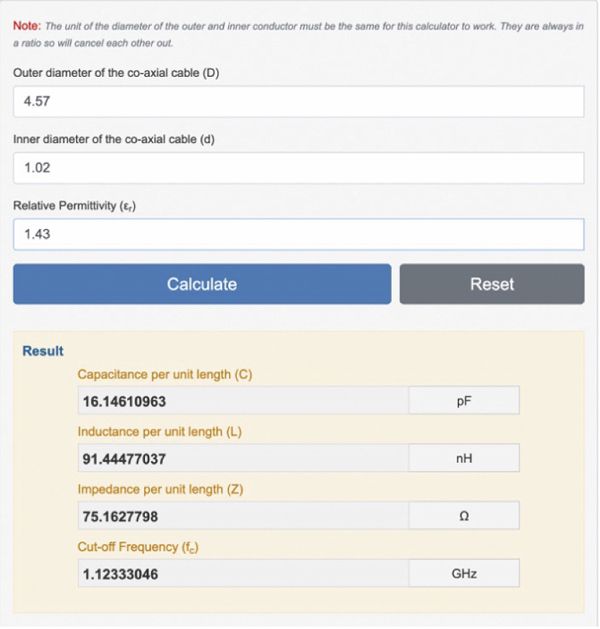

There are several online calculators available, such as this one: https://www.everythingrf.com/rf-calculators/coaxial-cable-calculator, that allow us to easily determine the shield inside diameter, center conductor diameter, and relative permittivity (or velocity of propagation) from the coaxial cable vendor’s website, as well as calculate other “ideal” parameters like impedance. In Figure 3, for example, we calculated the impedance of Series 6 coaxial cable using data from a vendor’s website.

Impact of staples in coax

The dimensions (D) and (d), are called “outer” and “inner” diameters respectively in Figure 3. Now, let’s go back to the topic of staples and kinks. For instance, in Todd’s example, he had many kinks in a cable due to it being improperly rolled up. Similarly, consider a scenario where a technician has used staples to neatly attach a coaxial cable along the side of a customer’s home with the intention of making the installation look neat. Only each staple makes a small two-millimeter kink on the coaxial cable, about the depth of a paperclip, which is barely noticeable to the installer. You can perform the calculations, but by changing the outer diameter in Figure 3 by just two millimeters, you will find that the coaxial cable’s impedance changes from 75 ohms to 46 ohms. This causes an impedance mismatch at each staple location resulting in micro-reflections.

Figure 3. Calculated coax impedance of 75.16 ohms based off vendor data.

True, the inner diameter may change slightly due to staple compression, but not nearly as much as the outer diameter. This means that the staple will significantly alter the coaxial cable’s characteristic impedance at each staple location. Similar to how water flows through a pipe, RF signals passing through coaxial cable will encounter resistance from staple dents and kinks. As a result, signals are reflected back to the cable modem, and power at the CMTS may be less than optimal. Signals being reflected back to the modem due to an impedance mismatch is known as a micro-reflection. The more staples or kinks there are, the more micro-reflections there will be.

The end result experienced by subscribers

What is the end result of this? Because signals are reflected back to the cable modem due to the impedance mismatches, the CMTS may detect less RF power from the cable modem at its receiver. As a result, the cable modem will be instructed to transmit at a higher power level. The CMTS will also instruct the cable modem’s pre-equalizer to compensate for signal reflections that interfere with cable modem transmissions. In severe cases, such as those mentioned by Todd, the cable modem may lack sufficient transmit power to reach the CMTS, resulting in a variety of problems that negatively impact the subscriber’s service.

The two most common problems are impaired mode and partial mode. When an upstream channel is degraded but not marked as unusable by the CMTS, it is in impaired mode. The modem is still locked to the upstream channel in this case, but it is experiencing a high level of uncorrectable codeword errors. As a result, voice, real-time video, and gaming applications are impacted.

Unless the subscriber is on a high-speed tier, losing just one upstream channel may not have a noticeable impact on their experience. However, losing multiple upstream channels can result in slow upstream and even slow downstream speed performance for the subscriber.

In either case, subscribers are likely to suffer from degraded QoE resulting in a truck roll to replace the damaged coaxial cable. Finding these types of impairments can be challenging. A piece of coax with staples or kinks from being rolled up improperly may look fine to the untrained eye. Tools like proactive network maintenance (PNM) make this type of impairment easily detectable.

What can be done to address this issue? One option is to follow Todd’s recommendations. Another option would be to avoid using staples altogether. Indeed, many cable operators no longer use staples, instead using specialized clips.

Brady S. Volpe

Brady S. Volpe

brady.volpe@volpefirm.com

Brady Volpe is Founder of The Volpe Firm, Inc and Nimble This LLC. He has over 25 years of broadband cable and telecommunications industry experience specializing in RF, DOCSIS, PNM, and Internet Protocol. Mr. Volpe has been providing a wide range of troubleshooting, design solutions, services and seminars for cable operators and broadband companies specializing in DOCSIS, System Design, PNM, and Troubleshooting. He is a highly respected published speaker, both domestically and internationally. He also hosts a popular industry YouTube and Podcast – “Get Your Tech On“. Mr. Volpe has a MSEE with honors and a BSEE.

image by author

Image of coax and circuit is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported, 2.5 Generic, 2.0 Generic and 1.0 Generic license