Inventing the (Fiber Optic) Future

The Inside Story About the Dawning of the Fiber Optic Era, from Pioneering Inventor Peter Schultz

Before 1972, the southern New York company Corning was known mainly for making TV picture tubes and for the iconic cookware bearing its name. But behind the scenes, the work of a small group of scientists was about to dramatically change the company’s legacy while redefining the entire field of telecommunications. Here, the renowned scientist Peter Schultz recounts how Corning sparked the fiber optic revolution, and explains how fiber remains an essential enabler of cable’s next era.

You were an Elvis wanna-be during your teen years in 1950s New Jersey. How in the world did you find your way into fiber optics research?

My mother had introduced me to the Explorers, an offshoot of the Boy Scouts. It literally changed my life. I went from being a guy with an Elvis Presley haircut to a guy with a flattop, and ended up getting some pretty good grades. Around that time a neighbor who was an engineer at Westinghouse encouraged me to study engineering. My parents couldn’t afford to send me to college, but I ended up getting some scholarships, and I got into Rutgers.

We can’t resist the classic college conversation-starter: What was your major?

I started in my sophomore year to study ceramics, but by the time I became a senior I was really intrigued by glass.

Why glass?

There were so many variations around glass; so many things you could do with it beyond the normal window glass and drinking vessels. By changing the compositions and putting specific additives in you could create whole new sets of physical properties and unique materials. I was just intrigued by that; it seemed to me an open area. Who knows what could happen?

You wound up getting a National Science Foundation fellowship to pursue a Ph.D. from Rutgers. What was your introduction to Corning?

There was a professor, Norbert Kreidl, a physicist who escaped the Nazis in Czechoslovakia in 1939. He ended up being head of materials and development at Bausch and Lomb. I was his first graduate student. He was a wonderful, stimulating guy who encouraged me to work in glass science. He said if I was going to work in glass I should work at the mecca, which was Corning. I went to work there in 1967.

How did fiber optics enter the picture?

When you step back into the 1967 time frame, all communications were basically either copper wire or coax. That was it. But the laser had just been invented, and it was clear very early to the telecom giants of the time — AT&T, ITT — that this laser might be able to be used for communications. There was a scientist named Charles Kao from Standard Telecommunications Laboratories in the U.K., and he and others recognized the potential from day one.

Which was?

That here you had a very pure source of light, which could be modulated at optical frequencies, and then you could carry a tremendous amount of information across those lightwaves.

Some work had already been done to this end.

The idea of using a core with a slightly higher refractive index than the cladding had been developed in the mid-1950s by a scientist named Larry Curtis from the University of Michigan and a few scientists at the American Optical Corporation. Charles Kao had tried using fiber optics for communication, but quickly realized you’d be lucky to get a signal to travel one meter before you needed a repeater. The goal was to have one percent of the signal come out at the other end, because that was enough to detect it and amplify it and send it on its way again. That’s called 20 dB per kilometer of attenuation. So the goal was to transmit 20 dB per kilometer. Well, we could go about 20 dB in just one meter. So to go to one kilometer seemed like an impossible goal.

But people persisted.

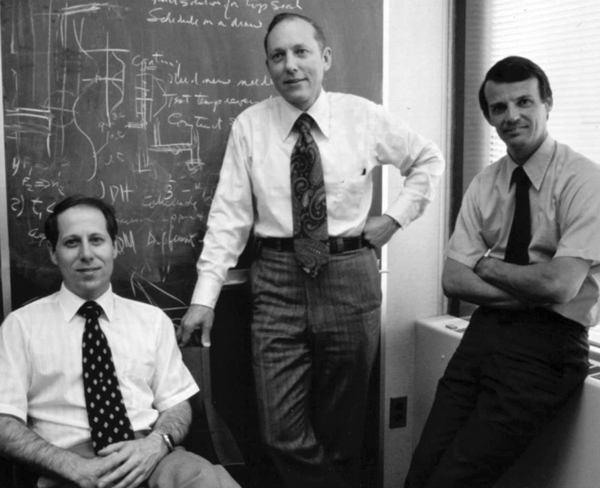

Charles Kao basically went around the country and the world to different laboratories trying to encourage people to work on this project. One of the companies he contacted happened to be Corning, which basically stimulated the head of the laboratory at that time to consider that just maybe we could do something. Bob Maurer of Corning started to work on it in 1966 in the research lab. I started working at Corning in 1967. By the beginning of 1968 Bob hired another physicist named Don Keck, and convinced my boss to let me get involved, because Bob felt he needed someone capable of making materials. Literally the three of us became the working team.

What did you guys try that hadn’t been tried before?

Almost all the laboratories working in glass technology or fiber were using what I’ll call conventional glasses, with multiple ingredients in them, like window glass, which can be readily melted at reasonable temperatures and pulled into fibers. The problem is they also contain all the impurities you find in the earth, like copper and so forth, all of which absorb light. Bob thought we should use a very simple glass, called fused silica. It requires extremely high temperatures to melt the glass and to pull it into fibers. There was a glass chemist in the 1930s at Corning who had come up with a process called flame hydrolysis vapor deposition. He started with a liquid and vaporized it. And out of that liquid came little particles of glass. We called it “soot.” It could be exposed in a furnace at a high temperature and you could make a nice chunk of fused silica. I was working on that process when Bob asked if I could help him out on this project. So we decided to use the flame hydrolysis process to make fused silica. After three-plus years, we came up with a process, using a vacuum cleaner in the lab, to make what we called a fiber preform: a thick-walled tube of silica which had been made by this flamed process to become the cladding of the fiber. Then to make the core, we added something to the silica glass in the flame to increase the refractive index: titanium oxide. So now we had this tube with a layer of doped glass on the inside surface.

Don Keck, Bob Maurer and Peter Schultz. e Corning ber research team circa 1973.

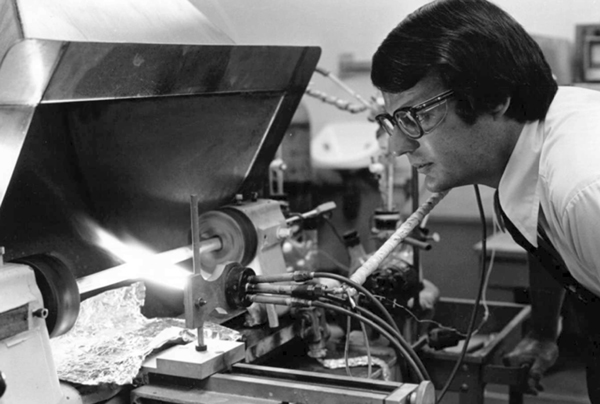

Peter Schultz with early OVD process lathe making a germania-silica ber preform.

Wait: a vacuum cleaner?

A canister vacuum cleaner. We pointed a flame into a tube and used the vacuum cleaner to suck those little particles of pure doped silica down the tube.

And?

And it worked. The first fibers that came out had attenuation of more than ten thousand dB per kilometer; so that was hardly a workable solution. But if you heated that fiber up, you could basically bleach it. When it oxidized, it basically cleared the glass and got rid of those absorption centers. And we ended up with an attenuation of 17 dB per kilometer. So we published that result in 1970. And no one believed it. The telephone companies all demanded to see the fibers firsthand. So Bob hand-carried a spool of fiber to all the big telephone laboratories. He would literally keep guard to make sure they didn’t snip pieces off and keep them.

But you still weren’t anywhere near commercial viability.

Not even close. All we had done was show that in principle, glass fibers could be made to get attenuation down in the range of copper wire. So it showed potentially these things could be used for communication. But there were so many hurdles still in the way. To make the fibers long enough to be useful, we didn’t know it was possible at all. The project was turned over from the research group to the development group, and when we explained to the development manager how we made these things, he said, “You’ve got to be kidding, right?” But in the research lab we kept working on it. Two years later I came up with the use of a different additive called germanium oxide. And instead of using a vacuum cleaner, I applied an alternative process called the outside vapor deposition process. In June of 1972 — I remember this very clearly — we made the first fiber from it. When the guys were pulling the fiber in the development lab, they said, “You’ve got to get down here and see this thing.” When we used titanium you’d be lucky to get 17 dB after a cumbersome heat treatment. But now they were saying you could still see a bright light coming out at the far end of this fiber straight off the draw tower. And sure enough, we took that fiber straight off the draw, measured the loss, and it was 4 dB per kilometer. The head of the development group said, “Now you’re giving me something.” To me that was really the breakthrough, using this outside vapor deposition process. It worked, and it was scalable. That basic germanium-doped silica core using a vapor deposition process is still used today to make all the fiber used for telecommunications.

Outside the lab, what did the marketplace look like?

In 1972 there were no personal computers, just big IBM mainframes that took up whole rooms. Handheld calculators didn’t even exist. But what we thought about at the time was that historically there’s always a need for improved bandwidth. If you plot bandwidth versus time from the first telephones of the late 1800s and looked at that curve, you realized that projecting forward, in 10 years or so, they were going to be running out of bandwidth. You just couldn’t squeeze enough out of coax and copper wire, even without knowing what exactly would cause the increased demand. Initially we were thinking that maybe we’d use fiber optics for some form of experimental video, like AT&T’s Picturephone, in the future. We knew that someday this was going to have a big impact. We just weren’t sure when “someday” was.

When was your first big sale?

The first really serious order for Corning was around 1976, by Northern Telecom in Canada. They placed an order for several thousand kilometers of fiber. When we got that order it seemed like trying to reach to the Moon. But we did it. Over time, companies like AT&T, GTE and ITT were all deploying it. By the mid-1980s it was finally a growing business.

And then?

And then three important things happened. The first was having a network that had sufficient resilience for high-bandwidth communications. The second was the invention of the personal computer. And the third was the development of user-friendly software. Those three things together triggered the Internet.

Going forward, what do you see for the future of fiber in the cable industry, specifically? Is the movement to fiber-to-the-premise architectures inevitable?

Absolutely. In my mind there’s no doubt about it. You can have wireless for a short distance, and certainly inside your home, but in my view it’s inevitable that demand for bandwidth is going to continue to go up and up. We have the Internet, we have the buildout of fiber, and now along comes the smartphone and all the apps that go with it, and people just gobble it up. Going forward there’s going to be demand for more and more apps: for ultra-high definition TV, for interactive TV technologies, for virtual reality, probably somewhere down the road for holographic video. That requires huge amounts of bandwidth, and you’re not going to do it on anything but fiber. I understand the value of trying to leverage the benefits you can from investments in coax and hybrid networks, but even advancements like DOCSIS 3.1 are still interim steps toward what’s ultimately going to be a fiber network.

How do you see cable playing a role in the future of fiber optic networks?

We’re actually at a very interesting juncture for the cable companies, and I’m sure they recognize this. With the development of the Internet and high-bandwidth communications, the whole world of telecommunications is in turmoil. The question is: Who can do what? It all kind of blends together. So now you have traditional telecom companies trying to basically offer a triple play themselves; and you have the cable companies that can also deliver a triple play. There’s a true opportunity for them if they’re aggressive. They’ve got to put the infrastructure in place. That means hard-wired fiber but also the software needed to offer various important services.

The trend lines would certainly suggest fiber is essential.

Here’s an interesting bit of statistics. It took from 1975 to 2008, or 33 years, to hit 1 billion cabled fiber kilometers installed. It took just five additional years to hit 2 billion kilometers. It took only three more years to reach 3 billion cumulative kilometers of cabled fiber installed. And this is not dot.com demand, this is real economics. It’s not being paid by borrowed money; but by real revenues being paid by using the system.

As you watch television or use the Internet, do you allow yourself to consider your role in making all this possible?

I sometimes do. Here at my home I have a connection that’s partly wireless, maybe for 100 yards, but the rest of it connects to a fiber network. Every time I turn on that TV, I know I’m using my fiber. In the event our signal ever goes down, I know it’s not because of a fiber problem, but my wife still turns to me and asks if it’s my fault.

What lessons can you draw from Corning’s initiative to bring fiber to the world?

It took a huge amount of courage. They literally bet the company in those early days. By 1975 we were building a pilot production facility even though we didn’t have any orders. Amory Houghton was CEO at the time. He was the fifth-generation Houghton to run the company since its start in 1851, and he really understood the value of technology. He recognized it was the inventions made by chemists and scientists that really opened the door to new businesses. Along with William Armistead, a senior vice president on the technology side, these really were the two chief executives of the company. Both of them recognized that fiber optics for communications really could revolutionize the company. As a result, Corning ended up in some major federal court patent cases, spending millions of dollars over several years to defend our patents at a time when Corning wasn’t a big company. If it wasn’t for Amo and Bill, it never would have happened.

Final thoughts?

Corning also recognized, and I think this is an important point, that you need to have within a company sort of a library of technology capabilities, and that you can build on that over time. The first basic invention that led to our breakthroughs in fiber was by a chemist named Frank Hyde, who in the 1930s, working as a scientist at Corning in a tiny research lab, had come up with this idea that maybe we could make glass by vapor deposition. Forty years later that was instrumental in how we invented modern fiber optics.

(Answers edited for brevity.)

Inventor Peter C. Schultz, Ph.D.

Inventor Peter C. Schultz, Ph.D.

Peter C. Schultz, Ph.D., is co-inventor of the fiber optics now used worldwide for telecommunications. He is an internationally-recognized scientist and has received numerous awards for his technical achievements. In 1993 he was inducted into the National Inventors Hall of Fame and in 2000 received the National Medal of Technology from President Clinton for his accomplishments (the highest technology award of the US government). In 1991, he was elected a member of the National Academy of Engineering. He is an expert in fiber optic technology (including telecommunication fibers and both terrestrial and undersea deployments, as well as specialty fibers for sensors) and general materials technology. He has been a resident of St Thomas since 2001.

He was President and Chief Technology Officer of Heraeus Inc. (1988-2001), the 900-employee US subsidiary of a multibillion dollar private German company serving the fiber telecom, semiconductor and optics markets. He was also VP Technology (1984-1988) for SpecTran Corp (a large Massachusetts-based fiber optics manufacturer) and Senior Scientist for Corning, Inc. (1967-1984).

Since 2001 he has provided technical and business consulting services to numerous international companies and expert witness for several law firms, through Peter Schultz Consulting, LLC. He serves (2001–present) as senior advisor and sole outside Board member of OFS Fitel (the $800M+ AT&T fiber optics business unit acquired by Furukawa in 2001) and as Director, Secretary and advisor (2010 to present) and Interim CEO (March through September 2016) of viNGN (Virgin Islands Next Generation Network), a government-owned company building and operating an open access all-fiber telecom system in the US Virgin Islands. He is also President of a research company (BioSensor Inc., founded in 1997) developing several novel medical sensors based on Russian technology. One of these devices is currently undergoing medical trials for treatment of autism in children.

He is a Junior Warden for Nazareth by the Sea Episcopal Church (since 2007) and served as a Trustee of All Saints School (2009-2011). He is a Director of the newly formed non-profit Virgin Islands Center for Arts and Technology on St Croix.

He is a graduate of Rutgers University (B.S.1964, Ph.D.1967) and the MIT Sloan School Senior Executive Program (1984). Peter Schultz holds 26 patents, has written over 22 research papers and is the recipient of numerous other awards recognizing his achievements, including the American Innovator Award (first recipient-US Dept. of Commerce 1995) presented by Ron Brown (Secretary of Commerce), and the Czech Gold Medal for Achievement presented by President Havel in 2002.

About the Interviewer

About the Interviewer

Stewart Schley,

Media/Telecom Industry Analyst

stewart@stewartschley.com

Meet Stewart Schley, a journalist who is no stranger to Broadband. For over 20 years Stewart has been captivating readers with his industry foresight and knowledge. He has a special talent for providing the best business profiles by sitting down… one on one… with his subject and getting the real story. If you missed his compelling interviews with John Malone or JR Walden check them out at broadbandlibrary.com in the archives section.

Source: Photos courtesy of Corning Inc.