Full-Band Capture Takes the Stage

By Jeff Finkelstein

For anyone who has been in cable a long time, for some of us a very long time, we remember how challenging it was to troubleshoot plant impairments in the headend and field. Not just in finding and correcting, but in dealing with the equipment we used in the day. The size, weight, and bulkiness of the test equipment we had to lug around was significant. We carried our sore backs as a badge of honor. Frozen fingers from connecting our test equipment into the plant in frigid weather was our nemesis as they cracked and bled from the cold. Sweating in the summer heat while we carried our heavy analyzers, protecting the test equipment from rain, wind impacting the impairments by swaying the long test cable we had to connect by gaffing up the pole.

For many technicians today, those days are merely apocryphal stories. Thanks to two recent (recent in the cable era) technologies, today’s techs are spoiled. I am of course talking about proactive network maintenance (PNM) and the topic of this article, full band capture (FBC) capability in newer modems. There are a number of articles in this issue that are delving into the background and use of PNM. This article discusses how FBC is used in the cable network.

As bandwidth demands increased on the cable network from new services like OTT, video conferencing, and higher data speed service, new silicon offerings with denser tuners and demodulators were created to meet that need. DOCSIS 3.0 became the new standard and pushed signal quality requirements to support channel bonding and spectrum usage up to 1 GHz.

As the silicon manufacturers were developing the new chips, they introduced a radical idea of using new digital tuners that could capture the entire spectrum, both upstream and downstream, allowing them to provide similar functionality to the large and expensive spectrum analyzers technicians were using. The DOCSIS 3.0 specification provided access to this new data and with appropriate software we were now able to collect and analyze the FBC information allowing us to view the RF spectrum as if we had a spectrum analyzer installed in the customer’s home or headend.

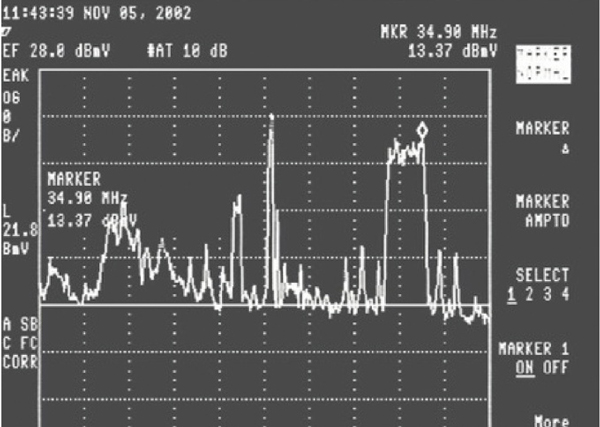

Figure 1. (*sigh*, I do miss my old 8591C spectrum analyzer…)

Applications of FBC

Using this new information, operators were now able to have a near real-time view into the downstream and upstream spectrum, seeing max/min/average power levels and set alarms based on thresholds. Combining FBC with PNM, we could now locate impairments in the cable plant and dispatch a technician to where the issues originated.

The new cable modem capabilities, along with a diagnostic mode enabled modem, allowed a single technician to tune the upstream plant by generating a continuous QAM signal from the modem and changing power levels to achieve the desired results. Overall network health was improved as the FBC and PNM pairing provided new tools that gave immediate feedback on plant conditions. Some vendors embedded these devices in their remote devices including nodes and power supplies, giving a ready source of “probes” that could not only generate test signals, but report on them at key outside plant locations.

Examples

A picture is worth a thousand words. First, if you remember pictures like the one shown in Figure 1, then you have been in cable for quite a while.

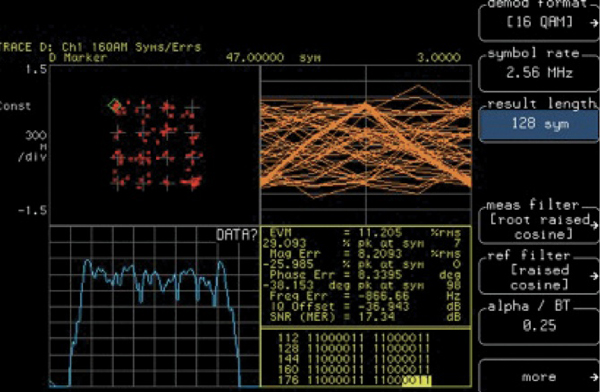

Figure 2. Vector signal analyzer display

Figure 2 shows a much more modern example using a vector signal analyzer.

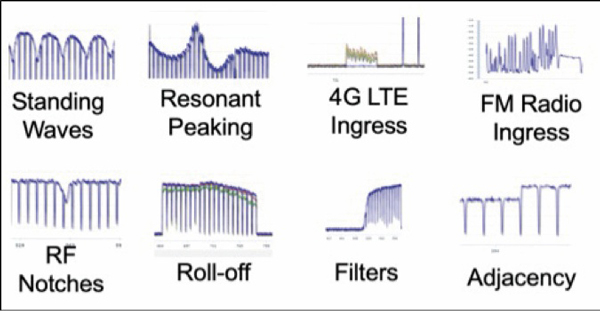

Figure 3. Examples of impairments in several FBC screen shots (courtesy of Comcast)

And finally, Figure 3 shows several examples of impairments from modems equipped with FBC capability.

Putting it into dollars, an old 8591C analyzer was around $15k, a vector analyzer in the $60k (or more!) ballpark, and a cable modem? About $50. Granted, you still need software to do the analysis, but thanks to CableLabs as part of the PNM project, they have code available for spectral impairment detection (SID) that can be downloaded from their website. The cost? Free to members of the PNM working group who have signed the NDA.

Conclusion

With the new capabilities introduced by FBC, the days of field personnel being required to carry expensive test equipment were no longer the norm. Handheld meters, spectrum analyzers, and CW tone generators were quickly becoming a relic of the past. Instead of being required to have a dedicated workforce to monitor and tune the cable network, cable operators were able to train all technicians to use the new tools and better manage the cable plant.

By using the new tools of FBC and PNM, along with software-based analysis, our most precious resources of field techs became our front-line defense to minimize outage time and dramatically increase customer satisfaction by finding and correcting issues before the customer ever noticed them.

Jeff Finkelstein

Jeff Finkelstein

Executive Director of Advanced Technology

Cox Communications

Jeff Finkelstein is the Executive Director of Advanced Technology at Cox Communications in Atlanta, Georgia. He has been a key contributor to the engineering organization at Cox since 2002, and led the team responsible for the deployment of DOCSIS® technologies, from DOCSIS 1.0 to DOCSIS 3.0. He was the initial innovator of advanced technologies including proactive network maintenance, active queue management and DOCSIS 3.1. His current responsibilities include defining the future cable network vision and teaching innovation at Cox. Jeff has over 43 patents issued or pending. His hobbies include Irish traditional music and stand-up comedy.