Finding More Capacity in OSP Fiber — the OSP AOM

By Jim Kane

AMPHENOL BROADBAND SOLUTIONS (Advertorial)

Amphenol Broadband Solutions

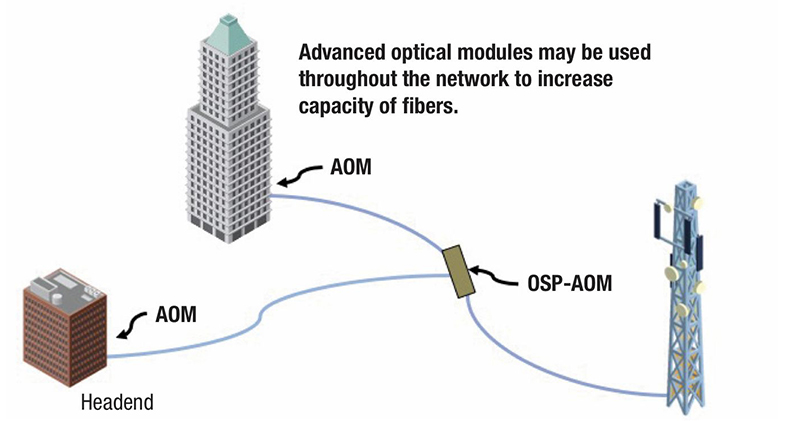

With the onset of the COVID-19 pandemic, cable industry distribution networks have been severely stressed due to the increased demand of telecommuters, students and others working from their homes. Where it is deployed, fiber capacity may be readily boosted through solutions such as dense wavelength division multiplexing (DWDM) without the need to place additional fiber, saving time and money, and providing more responsive service to both new and existing customers.

The distribution network may be limited, however, by the capacity available in its outside plant (OSP) splice closures, particularly those that are near or have already exhausted internal space. The need to provide a new closure as more capacity is added to a fiber route represents a significant investment in terms of both time and placement and splicing costs.

Amphenol Broadband Solutions expands the capacity of fiber with a DWDM solution that combines simplicity, security and reliability. Its new OSP AOM (advanced optical module) has been designed to handle high channel counts in a package which exploits and expands the capacity of many of the most popular OSP closures. By virtue of its port density and form factor, and utilizing previously unused space within the closure, the OSP AOM devices might very well save the cost of placement of additional closures.

The Amphenol OSP AOM joins the previously introduced HiDT xWDM packaging to offer solutions from four to 40 channels within a single form factor. The smaller HiDT is used in applications with channel counts of eight or less, while the OSP AOM will provide for channel counts that are higher than eight, all the way up through 48. Both packages provide stable optical performance across the wide operating temperature range necessary for OSP deployment.

A carefully planned set of accessories facilitate secure, reliable placement of the OSP AOM inside many of the most popular OSP closures. Unlike the typical approach of securing DWDM devices in OSP closures using Velcro, tape, or other clumsy solutions, every OSP AOM is mechanically mounted and provides an audible “click” to ensure safe, long-term service that will not become insecure as a result of temperature changes, re-opening of the closure, etc. This security will result in savings as trouble situations are avoided throughout the life of the DWDM device.

As an example of its versatility, the OSP AOM has two installation options within a widely deployed, industry standard OSP closure. The first method is placement with the stack of splice trays within the closure. To accomplish this, the module is snap-mounted in a module mounting bracket, which snaps onto the closure’s “tower” consuming a tray slot within the closure.

The second installation approach is to place the OSP AOM in the closure’s “slack basket.” In this case, the module is snapped into a mounting bracket, which is then secured by taking advantage of permanently open tower positions within the slack basket. Up to two OSP AOM modules may be added to a closure using this approach. The traditional function of the basket is not hindered since any slack stored there is typically dressed towards the basket’s outer walls, leaving the center of the basket to be occupied by the module(s). This approach provides even greater capacity within the closure than is offered by the manufacturer of the closure.

The OSP AOM provides convenient test ports at the most accessible end of the closure, eliminating the need to fumble with test access that may be located on splice trays or among the inter-tray fibers at the cable end of the closure. Troubleshooting craft will appreciate the convenience of these test ports, and the time-savings they provide will have a direct impact on operational expenses.

The OSP AOM provides convenient test ports at the most accessible end of the closure, eliminating the need to fumble with test access that may be located on splice trays or among the inter-tray fibers at the cable end of the closure. Troubleshooting craft will appreciate the convenience of these test ports, and the time-savings they provide will have a direct impact on operational expenses.

The OSP AOMs offer broadband service providers a cost-effective approach to increase the capacity of embedded fiber cable assets. By taking advantage of unused space within previously deployed OSP closures, each OSP AOM can offer up to 48 additional fiber channels. Mechanical mounting ensures that the OSP AOM, and its connections, are securely protected from the normal jostling that comes with other attachment methods. Finally, the convenient location of ports ensures hassle-free craft test access.

Jim Kane,

VP Product Management,

Amphenol Broadband Solutions

Jim Kane is the VP of Product Management at Amphenol Broadband Solutions, guiding the company’s optical product implementation strategy. In his 20+ years in the broadband industry, he has held leadership positions in Sales and Business Development. Amphenol Broadband Solutions is a global leader in communication technology development specializing in the engineering and manufacturing of cable, RF equipment, fiber optic products, OSP enclosures and wireless products.