A Hot Topic: Thermal Protection in OSP Enclosures

By Greg Worthman and Steve Skiest

As broadband service providers continue to extend infrastructure further to meet the growing bandwidth needs, network equipment is adapting to accommodate the greater distances and higher data throughput. Actives such as optical line terminals (OLTs) and RF amplifiers play a vital role in extending the signal farther but at much higher power consumption and consequently higher heat generation.

In many areas of the country, summertime temperatures can move to extreme levels, particularly in the south and west. For example, the average mid-summer high temperature in Phoenix is around 104 °F to 106 °F. Phoenix averages 111 days in which the high is at least 100 °F, and 21 days of at least 110 °F. In such circumstances, the outside plant (OSP) infrastructure is severely challenged.

The active elements in a hybrid fiber/coax (HFC) network enable a longer reach from the headend, yet it is these components that represent the largest engineering challenge in high heat environments. Actives require protection from the elements in closures that are large enough to accommodate them while also not being so large that they challenge the aesthetics of a neighborhood.

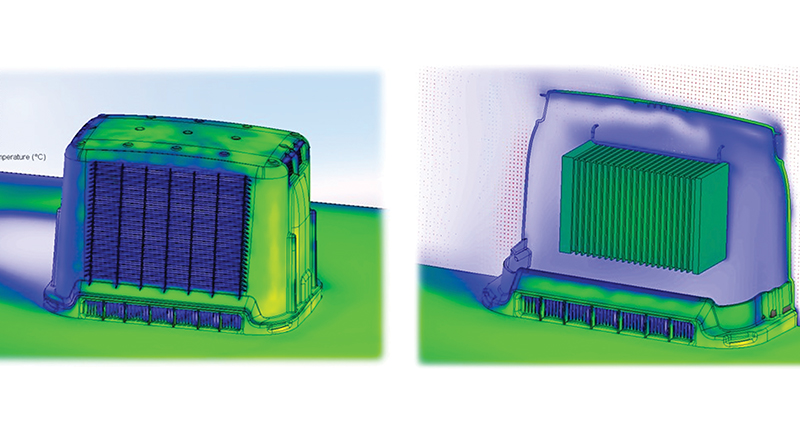

A common approach to protecting OSP equipment is to use pedestals which house equipment above ground level, offering ready access to technicians for troubleshooting or maintenance. While these pedestals may appear as simple plastic enclosures, when properly designed they can offer features that optimize airflow and minimize equipment overheating.

Network engineers along with their suppliers must be cognizant of the impact that extreme temperatures may have on OSP components. Further, they must explore mitigation strategies and product designs that will ensure continued network performance, even during the most challenging heat wave.

Next generation cable network upgrades, including distributed access architecture (DAA)-capable nodes place increasing thermal demands on OSP pedestal housings. The latest optical nodes are engineered to dissipate up to 160 watts of power, significantly greater than prior generations of pedestal housings were designed to accommodate. Pedestals that cannot accommodate 160 W may result in network outages and shortened lifespans for expensive electronics. OSP engineers are therefore challenged to not only determine proper size but also the thermal capacity of the pedestal.

Many pedestals may appear to be adequate in that they serve to “cover” sensitive electronics, and they may even do an adequate job of sheltering components from the elements. Challenges such as precipitation, blowing sand, vermin, and insects are only part of the puzzle. Relatively few closures have been engineered to specifically meet the complete demands of next generation broadband network equipment when it comes to thermal performance. Selecting a properly designed pedestal will limit equipment overheating issues as well as mitigate the need for ad-hoc modifications such as punching holes in deployed pedestals to ventilate heat. This approach, of course, provides an easy entry point into the pedestal for the aforementioned vermin.

When selecting a reliable housing for active devices, the network engineer should be concerned that the pedestal has been validated for passive thermal dissipation under worst case Telcordia GR-487-CORE OSP conditions to to 46 °C (115 °F). Further, with the growth of artificial intelligence (AI) and other bandwidth intensive applications expected to increase the power needs of OSP devices, one will be well served to select housings and pedestals that provide thermal headroom to futureproof, thereby avoiding pedestal replacement for the next generation of devices.

In conclusion, while many OSP pedestals may appear to provide adequate protection of valuable outdoor equipment, one must examine the design and engineering that provide all of the desired protection. Vendors with expertise in thermal analysis, design and testing will provide pedestals that are optimized for the best thermal performance.

Greg Worthman,

Greg Worthman,

Amphenol Broadband Solutions

Greg Worthman is Amphenol Broadband Solutions’ Product Management Director for RF components designed for the local area network in the home, and OSP enclosures for network transport equipment. He attended the University of Minnesota and has over 45 years in the cable industry.

Steve Skiest

Steve Skiest

Steve Skiest currently leads product management for Charles Industries, an Amphenol company, and a leading provider of enclosed solutions for the telecom industry. Mr. Skiest has over 30 years of technical application, product development, product management, and market development leadership experience within various sectors of the communications industry.