PONder the Future

By Robert Kuse

Today’s discussion offers a view of one cable operator’s FTTH journey. We’ll share some learnings and insights we have had on our path to 10G FTTH services via remote OLTs. You’ll see where we have innovated and where we have adopted more traditional approaches to FTTH technology choices. Perhaps this will help you in designing your own FTTH builds.

FTTH build activity in North America has finally come of age. New build activity has never been higher. Municipal governments, cooperatives, incumbent CLEC, telco, and cable providers — are all actively and aggressively building FTTH. FTTH build opportunity has even captured the interest of Wall Street. Newly created infrastructure funds are actively and aggressively initiating FTTH builds. This is happening everywhere — in rural, urban, and metro communities. FTTH is expected to grow from 40 million households passed to over 60 million households passed within the next 10 years.

New PON FTTH builds are also rapidly transitioning from GPON to 10G capable XGS-PON and EPON technologies. 10G PON equipment shipments now exceed GPON equipment globally. 10G PON is expected to totally dominate FTTH builds on a go-forward basis.

PON FTTH build strategies by service providers vary a bit and are worth mentioning. Despite nearly two decades of FTTH build activity, we are still in the early days of North American fiber builds. There is still a lot of opportunity for innovation in FTTH architecture and service delivery options. This includes considerations in

- OSP fiber design and split methodology

- Duct and drop methodology

- Pre-connectorized and fusion splice options

- Remote OLT and field cabinets designs

- Field aggregation versus all fiber builds

- Pre-lit versus service activation connected drop methodologies

Rapid growth is always a time of rapid innovation. It is exciting to see new ideas introduced. Solving labor, space, power, heat, and cost concerns are all on the table.

We are a large cable provider of Internet services. We first built PON services for commercial customers in 2008, originally adopting BPON technology. We initially built our PON networks with centralized OLTs and splitters. We reused available access fiber — all of it in a home-run topology. It was marketed as a low-cost alternative to our SONET, and Ethernet based transport options for our commercial optical Internet customers. We were early to address the needs of small and mid-size commercial customers with FTTX solutions.

We transitioned quickly to GPON when it became available, retiring the BPON networks. In 2014, we built our first brownfield residential GPON networks. We realized quickly that the 20 km optical budgets for GPON would limit our ability to use centralized OLTs. It would be necessary to build OLTs in field cabinets to extend the reach of our GPON networks. Field cabinet OLTs also reduced the need for trunk fiber augmentation required to support centralized splitting.

So, we built field cabinets capable of serving 6,000 to 8,000 households passed. The cabinets were very large. They included air conditioners to keep our equipment cool in our most demanding southwest markets. Summer temperatures regularly approach 115 degrees in that market. We built several hundred thousand homes with this architecture.

We soon realized these installations were costly to build. Increasingly difficult to permit. And subject to vandalism and chance meetings with trucks and automobiles. They were also expensive to operate. Energy costs were higher for the near constant air conditioning usage. And they needed frequent maintenance of filters and cooling components.

We also wanted to transition our FTTH aspirations to greenfield builds. We found the initial cabinet cost created challenging business cases for greenfield SFU/MDU build opportunities. Trying to scale them down to serve FTTH projects in a 100 to 500 homes passed range was difficult.

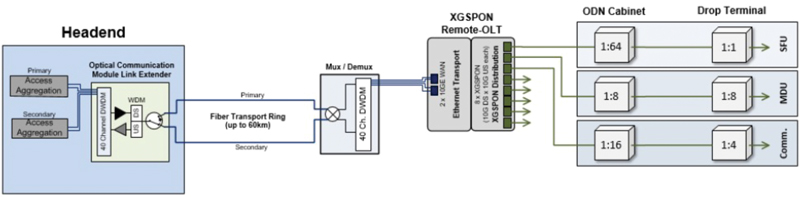

So, we innovated and worked with our vendors to build a remote OLT. It was similar in size and power consumption to our HFC fiber nodes. It used the same coaxial power system. The same fiber tails. And the same connector types used in our HFC plant node design. The fiber splitting was also moved to the field in small splitter cabinets.

In 2017, we deployed our first remote GPON OLTs in southern California. It worked really well. We stopped deploying cabinets shortly after that in all but our largest FTTH builds. And we have not looked back. We now pass several hundred thousand homes with remote OLT FTTH infrastructure.

Each of our remote GPON OLTs is an eight-port design. We deploy with a 64-way split design. We pass 512 homes with each remote OLT we deploy. In this configuration we no longer require filter and AC maintenance, nor the added cost of cooling. The large street cabinets have been replaced by smaller doghouse deployments. These are identical to the ones we use for our HFC DAA deployments. We deploy a single active device for 512 homes versus the several dozen that would exist in a DOCSIS design or the dozen or so that would be deployed in our N+0 DAA architecture.

We started a program to do FTTB overbuilds in our dense commercial DOCSIS nodes. This is a method to alleviate accelerated congestion issues. It provides a better user experience with a wider range of symmetric speed tiers.

To evolve these GPON FTTB brownfield overbuild nodes, we anticipated the need for these customers to demand higher penetrations of gig and even multi-gig speed tiers. These discussions drove our decision to look for a 10G XGS-PON solution for our greenfield and brownfield FTTX projects.

In early 2019 we launched an RFP for a 10G XGS-PON remote OLT solution. In December 2020 we launched our first residential XGS-PON remote OLT in our Central Region. Throughout 2021 we have expanded our XGS-PON builds across our entire footprint. With few exceptions, we are no longer designing new GPON and HFC nodes in any of our regions. Our greenfield builds going forward are exclusively XGS-PON remote OLTs.

The final question for our FTTH engineering team was how to upgrade all existing GPON cabinet-based and GPON remote OLTs to XGS-PON. We previously upgraded our optical splitting and distribution network architecture to include co-existence filters. We were anticipating the day when we would add next generation PON capabilities as an overlay.

In late 2019 we saw early demonstrations of combination port GPON/XGS-PON line cards. These cards combined both GPON and XGS-PON into a single port. They incorporate a single optic with the upstream and downstream wavelengths to simultaneously support both wavelengths. Combi-port cards would obviate the need for co-existence filters and would require no additional space or power.

We worked with our vendors on upgraded hardware designs for our remote OLT to include combi-ports. This would allow us to do field upgrades of remote OLTs that would not require additional power, vaults, right of way or doghouse placements. Customers already receiving GPON services would not experience any change in service. They could be migrated to XGS-PON at a future date. We have begun to upgrade our entire brownfield GPON network to combi-port cable XGS-PON and expect that to take a few years.

Our journey to FTTH has taken us through three generations of PON. We have moved from centralized splitting to a distributed model. We have moved our OLTs from the core to the field. We remotely manage all our field OLTs. We have built the capability to auto-provision them with zero-touch activation. We have been able to rapidly scale our FTTH build capability without the need for costly fiber trunk augmentations. We have successfully cross-trained our HFC and fiber technicians to support our FTTH builds. Remote OLTs with combi-ports have been a real game changer for us. They might make sense in your future FTTH builds, too.

Robert Kuse

Robert Kuse

Sr. Director, Access Engineering

Cox Communications, Inc.

Robert leads the Cox access engineering team that manages the technical deployments for Cox FTTH builds for both residential and commercial customers. Robert previously led the Cox commercial services engineering that built a national Cox Business services backbone and metro access network. He started his career at BellSouth and later AT&T. He was part of the product management team that launched DSL services as well as the initial fiber-to-the-cell site builds. He is a former board member and treasurer of the Metro Ethernet Forum.

Shutterstock